Now imagine if those products were made at western labour rates - would you be prepared to pay for a £10,000 notebook? Think about how computers dominate our lives, the effect on the world economy and what life would be like in every aspect if we couldn't mass produce inexpensive PCs. It's a strong moral question that certainly incites a lot of debate.

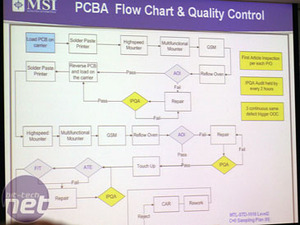

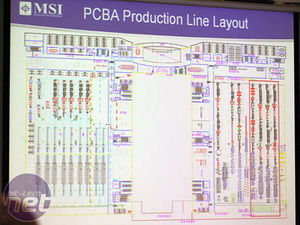

The PCBs themselves are made elsewhere, but the main electrical components are drawn from large tape reels and are rapidly placed in position by machines at about five per second. The machine "looks" at the board and the reels are barcode scanned so it always knows exactly where it is.

After the first lot of resistors, ceramic capacitors and mosfets are dropped on, the larger capped capacitors are dropped in by hand, then on goes the larger components like the northbridge, southbridge and major chipsets.

It's really quite strange to see a whole reel of P35s get sucked round at spat out - I gave up trying to count how many loops there were - because I wanted to know how many P35s were on each reel, giving me how much it cost!

After this there was PCI slots, memory slots, CPU socket and rear I/O put into place by hand, then finally the whole thing is passed through a wave solder machine to secure everything down. The excess solder is then buffed off and the underside smoothed of hard edges, before the board is connection checked to make sure it works. In all, a single board can pass through in about 15 minutes, but there are dozens on the line at any one time.

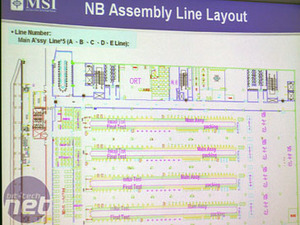

The notebook assembly is a lot more manually intensive as it's built up progressively by hand, even though each person does a single job like screwing down the motherboard, installing the memory, applying thermal paste, or clipping down the plastic panels. In fact, it takes the same amount of line space to assemble and pack it, as it does to doing simple tests to check the entire system works correctly - audio test, every-single-key keyboard test (imagine having a mash keyboards all day), display, ports, touchpad etc - it all gets looked at.

This doesn't really mean that notebook manufacturing takes twice the space as motherboard manufacturing because people typically take up less space then machines, and the line goes up one side and down the other. Ingeniously, MSI uses the centre column between both the lines to test the power adapters and notebooks charging capability, so the available space is efficiently used.

The PCBs themselves are made elsewhere, but the main electrical components are drawn from large tape reels and are rapidly placed in position by machines at about five per second. The machine "looks" at the board and the reels are barcode scanned so it always knows exactly where it is.

After the first lot of resistors, ceramic capacitors and mosfets are dropped on, the larger capped capacitors are dropped in by hand, then on goes the larger components like the northbridge, southbridge and major chipsets.

It's really quite strange to see a whole reel of P35s get sucked round at spat out - I gave up trying to count how many loops there were - because I wanted to know how many P35s were on each reel, giving me how much it cost!

After this there was PCI slots, memory slots, CPU socket and rear I/O put into place by hand, then finally the whole thing is passed through a wave solder machine to secure everything down. The excess solder is then buffed off and the underside smoothed of hard edges, before the board is connection checked to make sure it works. In all, a single board can pass through in about 15 minutes, but there are dozens on the line at any one time.

The notebook assembly is a lot more manually intensive as it's built up progressively by hand, even though each person does a single job like screwing down the motherboard, installing the memory, applying thermal paste, or clipping down the plastic panels. In fact, it takes the same amount of line space to assemble and pack it, as it does to doing simple tests to check the entire system works correctly - audio test, every-single-key keyboard test (imagine having a mash keyboards all day), display, ports, touchpad etc - it all gets looked at.

This doesn't really mean that notebook manufacturing takes twice the space as motherboard manufacturing because people typically take up less space then machines, and the line goes up one side and down the other. Ingeniously, MSI uses the centre column between both the lines to test the power adapters and notebooks charging capability, so the available space is efficiently used.

MSI MPG Velox 100R Chassis Review

October 14 2021 | 15:04

Want to comment? Please log in.